Production Process

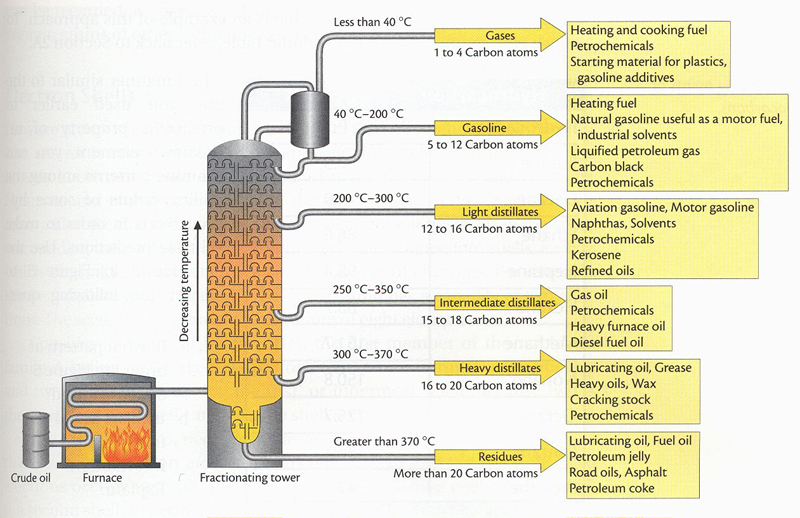

Bitumen is produced by fractional distillation of crude oil. Usually, distillation is done in two steps. First the crude oil is heated up to 300-350°C and introduced into an atmospheric distillation column. Lighter fractions like naphtha, kerosene and gas oil are separated from the crude oil at different heights in the column. The heaviest fractions left at the bottom of the column are called heavy residue.

The long residue is heated up to 350-400°C and introduced into a vacuum distillation column. By using reduced pressure it is possible to further distillate lighter products from the residue because the equivalent temperature (temperature under atmospheric conditions) is much higher. If second distillation were carried out under atmospheric conditions and by increasing the temperature above 400°C, thermal decomposition/cracking of the heavy residue would occur. The residue at the bottom of the column is called short residue and is the feedstock for the manufacture of bitumen.

The viscosity of the short residue depends on the origin of the crude oil, the temperature of the long residue, the temperature and pressure in the vacuum column and the residence time. Usually, the conditions are such that short residue is produced with a Penetration between 100 and 300 dmm. The amount of short residue decreases and the relative amount of asphaltenes increases with increasing viscosity of the short residue.

Bitumen manufactured from the short residue is called Vacuum Bottom. The differences in properties between high and low penetration grade bitumen are mainly caused by different amounts of molecule structures with strong interactions. Low penetration grade bitumen contains more of these molecule structures.

A second distillation, at reduced pressure, may be used to remove additional amounts of the more volatile products and create vacuum residues of the desired consistency. These one-stage and two-stage distilled asphalt fractions are referred to as straight-run bitumen, because the bitumen is separated from the crude oil while preserving its chemical properties. Different crude oils contain different quantities of vacuum bottom and require specific refining techniques to produce the desired straight-run bitumen. Oxidized bitumen from the bottom of the reactor is sent to the separator, where bitumen vapors are separated which are returned to reactor and then to storage Straight-run bitumen, constitutes oxidized bitumen, the basic material that may be tailored for specific paving or industrial demands. Because oxidized bitumen is a viscous, semisolid material, it is difficult to mix with other substances at ambient temperatures. By heating it, the oxidized bitumen may be made more liquid and can coat aggregates to produce hot-mix paving materials. Other methods to reduce oxidized bitumen’s viscosity are to disperse particles of it in water (emulsified bitumen) or to dissolve it in petroleum solvents (cutbacks bitumen). The volatility of the petroleum solvent determines the speed with which the cutback bitumen cures. Bitumen may be modified by exposure to air while the bitumen is at an elevated temperature. The resulting dehydrogenation and polymerization yield a material known as blown or oxidized bitumen. Blown bitumen display greater flexibility, less brittleness, and less susceptibility to changes in weather. They are commonly used in roofing applications, as the process raises the softening temperature of the asphalt and decreases the penetration rate.

Bitumen is also produced by propane deasphalting and there are differences in the properties of bitumen prepared by propane deasphalting and those prepared by vacuum distillation from the same feed stock. Propane deasphalting also has the ability to reduce a residuum even further and to produce a bituminous product with lower viscosity, higher ductility, and higher temperature susceptibility than other bitumen, although such properties might be anticipated to be very much crude oil dependent. Propane deasphalting is conventionally applied to low-bitumen-content crude oils, which are generally different in type and source from those processed by distillation of higher-yield crude oils.

The properties of bitumen can be modified by air blowing in batch and continuous processes. On the other hand, the preparation of bitumen in liquid form by blending (cutting back) bitumen with a petroleum distillate fraction is customary and is generally accomplished in tanks equipped with coils for air agitation or with a mechanical stirrer or a vortex mixer. Air is heated up to 150–250°C and introduced at the bottom of a blowing column. It then migrates through the bitumen to the top of the column. The chemical reactions result in bitumen with a different mixture of molecular structures. Catalysts can influence this process.

Blown bitumen has more and stronger molecular interactions than the original bitumen and is therefore more cohesive. Blowing causes the softening point to increase and the penetration to decrease. However, the increase in softening point is usually more than the decrease in penetration. This means that blowing reduces the temperature susceptibility of bitumen. The effectiveness of blowing depends largely on the original bitumen (i.e. the original mixture of molecular structures). With respect to the composition, generally the amount of saturates do not change, the amount of aromates decreases because some oxidized aromates behave like resins, the amount of asphaltenes increases due to trans-formation of some resins and the total amount of resins stays the same.

When bitumen is strongly blown it becomes so cohesive that the adhesive properties become so poor that it is not suited for asphalt applications anymore. Therefore, only semi-blown bitumen is suited for asphalt applications. Semi-blown bitumen can have both improved cohesion and improved adhesion..

Light products have a higher selling value than heavy products like bitumen. Visbreaking is a way to break heavy products (e.g. the residue from crude oil distillation or even very heavy crude oils) into lighter products. Hereto, the crude oil or residue is heated up to 450 °C and kept at that temperature for 1 to 20 minutes. During this period a large amount of molecular structures are broken into smaller structures. The product from the visbreaking process (VB product) is further normally distilled.